Products

Enpro is the technology leader in the application of release strips, also known as self-adhesive closures, pressure-sensitive adhesive closures or elasticated closures.

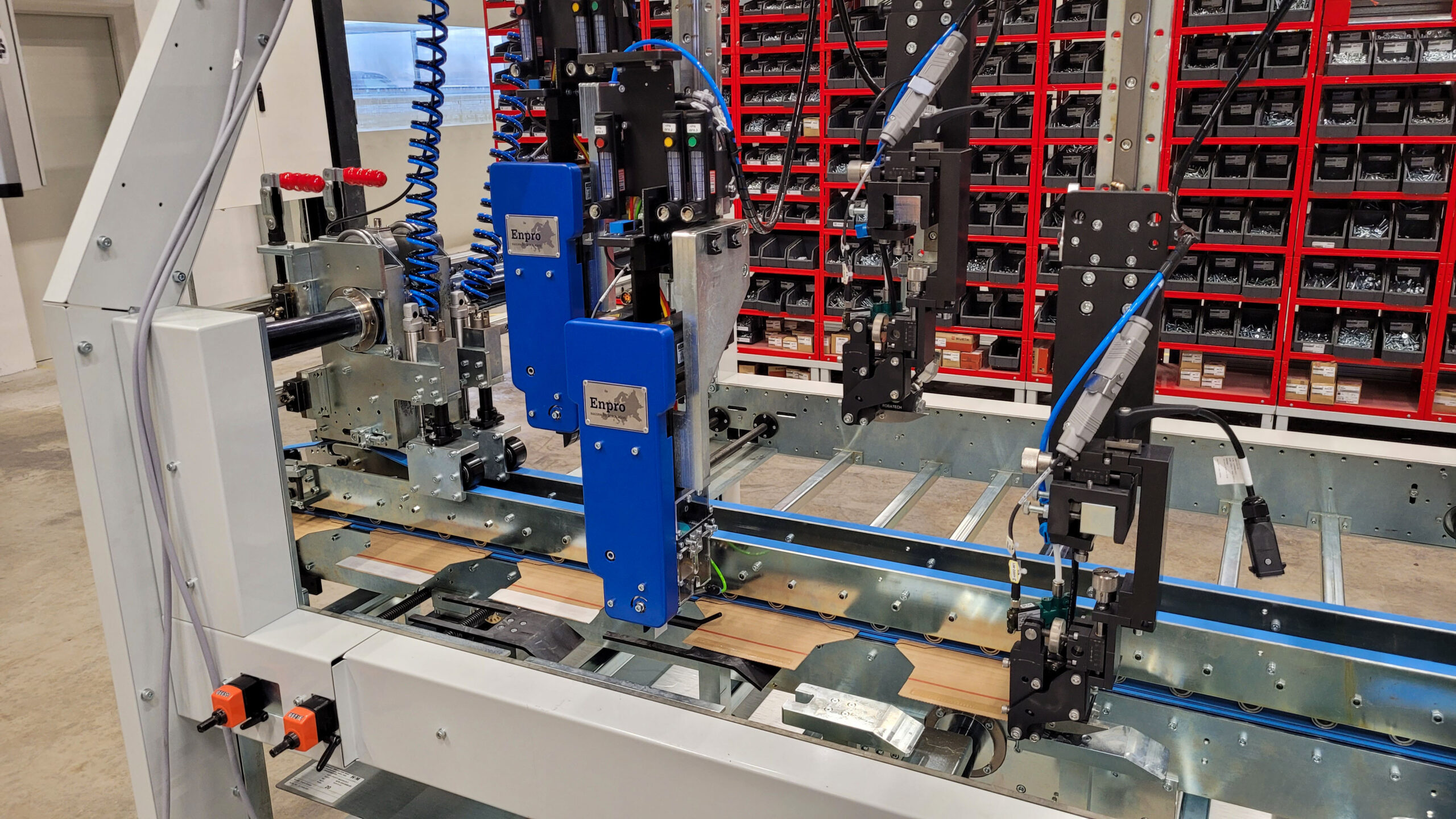

Special Machinery

We also offer customised solutions and special machine construction that are not directly related to mail order or e-commerce.

MANUFACTURING

We are equipped with the appropriate machines for the manufacture of plant components and for turning and milling work in contract manufacturing.

Our Company

Enpro is the technology leader in the application of release liner (silicone paper), also known as self-adhesive closure, pressure-sensitive adhesive closure, adhesive closure.

We have also developed new technologies for the tear strip that allow dispensing on paper bags at the same high production speed.

We also offer special solutions and special machine construction that are not directly related to mail order or e-commerce.

Our History

ENPRO – How did the company come about?

Enpro GmbH was founded in 1997 by the brothers Johannes and Albert Slot. Based on Johannes Slot’s experience in the envelope machine industry, production machines of the W&D and Paulzen brands were relocated and overhauled in the first few years. Johannes Slot’s mechanical and technical knowledge is complemented by Albert Slot’s practical and theoretical knowledge of electrical engineering. Both company founders are still involved in all projects and guarantee the highest quality and planning reliability.

A workshop was set up in 2000, enabling the company to offer customers machine conversions. To date, various CNC-controlled cutting machines have been purchased in order to be able to process orders in contract manufacturing and assembly production.

‘success by innovation’ – ’Success through innovation’

The pioneering success of our product developments for the packaging industry and our steady growth made a move to larger premises unavoidable.

We moved into a new building in Wilsum at the end of January 2019.

Almost all mechanical engineering tasks can now be solved in the current, modern workshop.

ENPRO – Where does the name actually come from?

As envelope machines were often relocated and overhauled during the company’s founding period, this is where the name came from:

EN from ‘ENVELOPE’ (English for: envelope)

PRO from ‘PROJECTS’ (English for: projects)

International Paper Board industry – may/june 2025

International Paper Board Industry – may/june 2023

Grafschafter Nachrichten

Mai 2023

International Paper Board industry – March/april 2023

International Paper Board Industry – May 2022

Grafschafter Nachrichten

November 2019

Wirtschaft aktuell – Mai 2019

Own developments for the packaging industry

“success by Innovation”

Thanks to the company’s many years of experience in the envelope and packaging industry, a number of newly developed products have been designed and manufactured in response to a wide range of customer requests.

This is a customisable application system consisting of various units:

a WTB – angular conveyor belt,

a MAS – Multiapplication System

and a TSA – Tear Strip Applicator.

These machines are used in particular for processing environmentally friendly cardboard and paper packaging.

WTB – Angle Conveyor Belt

The WTB (German: Winkeltransportband) is designed for conveying, diverting and processing packaging materials with high production speeds and various format sizes.

At the heart of the machine – the transport track – usually tear tape threads, hot melt and one or more release paper strips are applied to the packaging blanks which are deflected by 90°.

Product Details

Thanks to its mobility, the angle conveyor belt system can be flexibly integrated into existing production lines and can accommodate additional units.

Manifold functions and possibilities:

- Transport of packaging blanks at high school

- 90° deflection

- Separation of blanks from the shingle team

- Integration of glue application units

- Integration of MAS aggregates for the application of release paper strips

- Integration of TSA agggregates for the application of tear-off threads

- Return of blanks to the shingle stream in the usual direction

if necessary, transport straight ahead via bypass function – if redirection and processing are temporarily not desired.

If you are interested or if you have questions or suggestions, please do not hesitate to contact us. We will be happy to help you.

MAS – Multiapplicationsystem

A MAS is used for applying non-adhesive material strips of paper or plastic to a glue line. By using the

MAS you can realize both so-called self-adhesive closures (glue line covered with release / silicone

paper strips) and tear-off thread (glue line covered with paper or plastic strips).

Productdetails:

- Speed: up to 300m/min

- Tolerances: Length ± 0,25mm position ±2mm

- Strip width: 6mm-150mm

- Strip length: from 110mm (from 60mm is possible with special devices and appropriate parameter settings)

- Type of winding: disk rolls and cross winding spools

- Core diameter: 76mm (disk rolls) 152mm (cross winding spools)

- Core wide: 15-50mm (disk rolls) 180/250/300mm (cross winding spools)

- Material width: 15-50mm (disk rolls) 15-30mm (cross winding rolls)

It is possible to apply up to 5 strips in a row on a blank.

if you are interested, or if you have questions or suggestions, please do not hesitate to contact us.. Special requirements are also possible. We are looking forward to help you.

TSA- Tear Strip Applicator

A Tear Strip Applicator consists of a dispenser and an application head for the tear strip. Our machine is also known as a tear tape applicator, tear strip dispenser, tear tape dispenser and processes tear tape. The TSA dispenser holds the tear tape roll in place and feeds the tape tension-free to the application head. The TSA-application head ensures trouble-free application of the tape to the carrier material (cardboard packaging, etc.).

Productdetails:

- Speed: up to 170M/min

- Tolerances: Length ± 2mm, Position ±3mm

- Strip width: 4mm-6mm (other widths available on request)

- Strip length: 60mm – endless

- Type of winding: cross winding spools

- Core diameter: 152mm

- Core wide: 180mm

If you are interested, or if you have questions or suggestions, please do not hesitate to cantact us. Special requierments are also possible. We are looking forward to help you.

Enpro worldwide

Complete Systems

WTB

81

Aggregates

MAS, TSA, SPA

728

Countries

27

Machine Park

All necessary work, such as welding work for the production of system components and electrical controls, is carried out in-house by our own personnel. We are equipped with the appropriate machines for the manufacture of corresponding system components and for turning and milling work in contract manufacturing.

The result is high quality production and a schedule you can rely on..

CNc Milling

Okuma MU4000V

Technical Data:

- Cear of Construction 2023

- Control Okuma

- Speed (U/min) 15.000

- Traverse X (mm) 762

- Traverse Y (mm) 460

- Traverse Z (mm) 460

- Tool holder MAS BT40

- Tool places in magazine each 268

- Rapid Traverse X/Y/Z (m/min) 50

CNC Milling

CNC Vertical Center

Technical Data:

- Year of Constriction 2018

- Control Okuma OSP-P300MA-e

- Speed (U/min) 12000

- Traverse X (mm) 1050

- Traverse Y (mm) 560

- Traverse Z (mm) 460

- Working Area (mm) 1300×560

- Tool holder MAS BT40

- Tool places Magazine 32

- Rapid Traverse X/Y/Z (m/min) 40

CNc Milling

DMG EcoMill 50

Technical Data:

- Year of manufacure 2016

- Control Heidenhain TNC 620

- Speed (U/min) 12000

- Travel X (mm) 500

- Travel Y (mm) 450

- Travel Z (mm) 400

- C axis 360

- B axis -5 bis +110

- Clamping surface (mm) 630×500

- Spindle Power 83Nm

- Tool holder SK40

- Tool places in magazine 32

- Workpiece weight max. 200kg

- Rapid Traverse X/Y/Z (m/min) 24

CNc Milling

DMG Mori CMX 70 U 20kg 6-Achs Roboter Cellro Xcelerate X20

Technical Data

- Year of Manufacture 2018

- Control Siemens 840D

- Speed (U/min) 12000

- max. x-axis Travel (mm) 750

- max. y-axis Travel (mm) 600

- max. z-axis Travel (mm) 520

- C-Axis 360

- B-Axis -10 bis 95

- max. Table Loading (kg) 350

- Table diameter (mm) 800

- Tool holder SK40

- Tool places in Magazine 32

- Rapid Traverse X/Y/Z (m/min) 30

CNC Turning

Okuma LU3000 M2SC1000

Technical Data

- Year of Manufacture 2018

- Control Unit OSP-P300LA

- Traverse Paths Revolver 1 with 12 Stations (driven Tools) Revolver 2 with 8 Stations

- Turning Length: approx. 1000mm

CNc Turning

Okuma Genos L300E-M

Technical Data

- Years of manufacture 2016

- Control Unit Okuma OSP-P300L-R

- Traverse Paths Revolver 1 with 12 Stations (driven tools) Part ctacher for workpieces cut from the bar

- Turning range Ø300x1060mm

- Bar machinig max. Ø68mm

CNc Turning

Okuma L300 MYW und Samsys Kurzstangenlager

Technical Data:

- Year of construction 2020

- Control Okuma OSP-P300

- Traverse Paths Revolver with 12 Stations (driven Tools)

- Turning Range (mm) Ø210×300

- Bar machining Ø50x1000mm

Production areas

Planning and development

Thanks to years of experience gained in a wide variety of areas of mechanical engineering, we are able to design and develop machines and assemblies for you that incorporate the wealth of experience gained from countless projects.

Our market position is strengthened by our own developments of various units and feeding systems, which are based on our many years of experience in the construction of special machines for the packaging industry.

We would be happy to advise you in a non-binding discussion.

From design and project planning to the finished machine or system, whether for partial or complete processing – we are there for you!

Special Machinery

IThe interests of our clients are at the centre of our work. Right from the project planning and development stage, we orientate ourselves entirely to your specific requirements and specifications. We use our own machines to manufacture components, such as housings and devices for mechanical and electronic control systems, as well as entire assemblies for machine and plant construction.

We are happy to advise you from the entire design and production chain through to assembly.

We can manufacture any product you require.

Assembly production

The quality of the workpiece can be increased by incorporating special supplier expertise and the processing costs can be reduced. Here too, we are happy to advise you from the entire design and production chain through to assembly.

Contact Person

Get in touch with us now. Give us a call or send us a convenient e-mail, our contact partners are looking forward to your enquiry!

Managing Director/ Sales

Albert Slot

Telephone: +49 5945 99510-101

E-Mail: albert.slot(at)enpro.de

Managing Director/ Construction

Johannes Slot

Telephone: +49 5945 99510-141

E-Mail: hannes.slot(at)enpro.de

24-hour customer service

Telephone: +49 5945 99510-121

Whatsapp: +49 1721898174

E-Mail: service(at)enpro.de

Spareparts

Job Title

Telephone: +49 5945 99510-122

E-Mail: spareparts(at)enpro.de

Our Partner

AB System Polska Sp. z o.o.

ul. Wolnosci 18

64-130 Rydzyna

Polen

Plegaservice Center S.L.

C./ Masia Can Coll, 9

08620 Sant Vicenc dels Horts

Spanien

Brändström

60, avenue Charles de Gaulle CS 60016 92573 Neuilly-Sur-Seine Cedex Frankreich

NCA Hellas

l. Polemi Str. 5

GR14451 Metamorfosi Athens

Attica